Услуги

Мы оказываем широкий спектр услуг в рамках своей специализации

Мы имеем 2 передвижные установки термообработки по 70 кВА каждая на 6 каналов независимого программирования режима термообработки и выезжаем на места производства работ

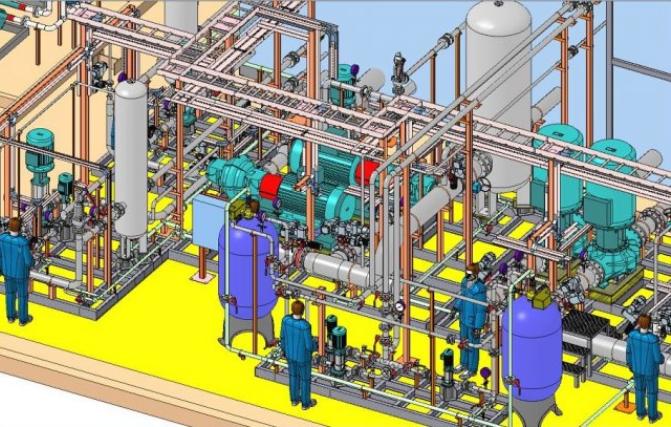

Проекты "под ключ"

Надежный партнер

Индивидуальный подход к каждому пожеланию и требованию Заказчика

Быстрая реакция на запрос